Menu

Product categories

Cart

WL20e Articulated Wheel Loader – Canopy

The WL20e wheel loader model is the first purely electrically operated wheel loader from Wacker Neuson. As with all of our wheel loaders, it convinces through first-class performance. Two electric engines, one for the drive system and one for the work hydraulics, ensure that the performance features of the WL20e correspond to those of the conventional machine. At the same time, the wheel loader works completely exhaust free and with significantly lower noise emissions. For the end user, this means greater flexibility in application, environmental protection and significant savings with operating costs.

– 100% emission-free thanks to wireless battery drive system

– Up to five hours of running time.

– Comparable performance as with conventional wheel loaders.

– Up to 41% savings in operating costs as well as cost advantages in maintenance and in the service intervals.

– Significantly lower noise pollution.

Engine / Motor | |

| Travel drive motor – capacity S2 (60 min.) | 6.5 kW |

| Lifting motor – capacity S3 (15%) | 9 kW |

Electrical system | |

| Operating voltage | 12 V |

Weights | |

| Operating weight | 2,350 kg |

| Tipping load with bucket – machine straight | 1,509 kg |

| Tipping load with bucket – machine at angle | 1,251 kg |

| Tipping load with pallet fork – machine straight | 1,112 kg |

| Tipping load with pallet fork – machine at angle | 916 kg |

Vehicle data | |

| Bucket capacity (standard bucket) | 0.2 m³ |

| Traction drive | electrically via universal joint shaft |

| Axles | T80 |

| Drivers cab (optional) | FSD (EPS, EPS PLus) |

| Speed | 0 – 15 km/h |

| Speed level | 1 |

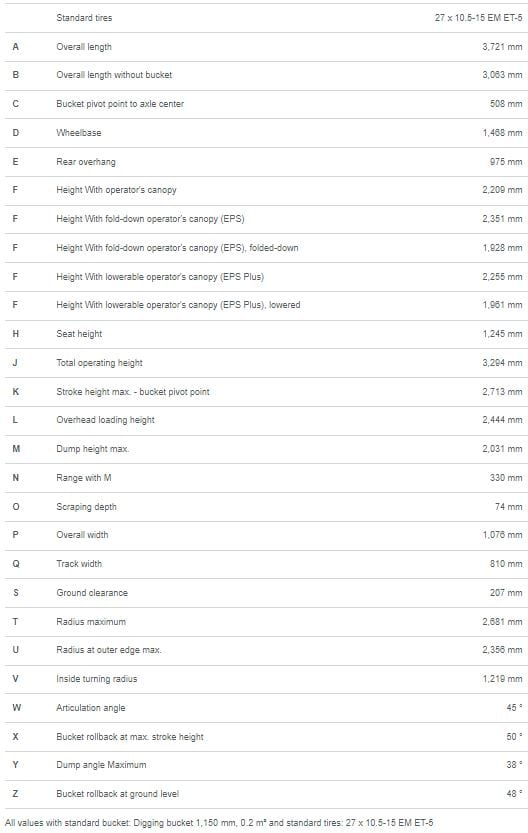

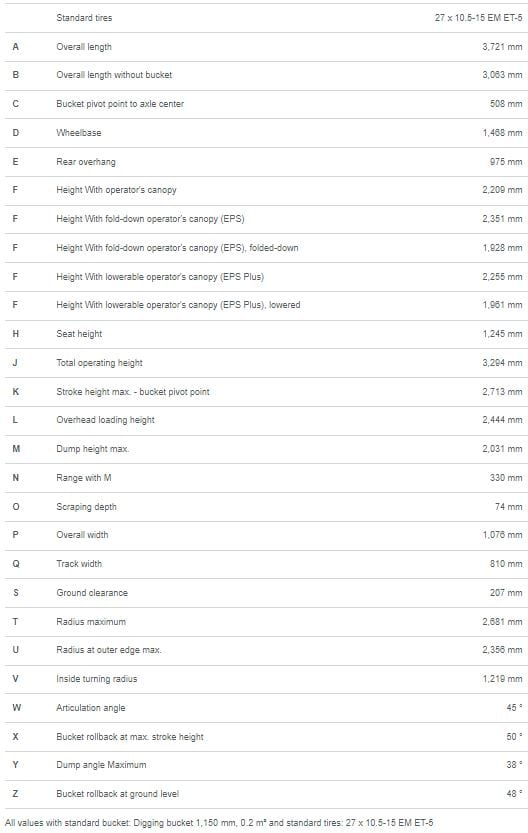

| Standard tires | 27 x 10.50-15 EM ET-5 |

Hydraulic system | |

| Operating hydraulics – operating pressure | 225 bar |

| Operating hydraulics – discharge capacity | 32 L/min |

Filling capacities | |

| Hydraulic oil tank | 18.5 L |

| Hydraulic system | 37 L |

Standard bucket = digging bucket, 1,500 mm width

FSD = operator’s canopy

EPS = Easy Protection System (fold-down operator’s canopy)

EPS Plus = Easy Protection System Plus (hydraulically lowerable operator’s canopy)

Tipping load calculation according to ISO 14397-EN474-3

*The running times of the battery are strongly dependent on the respective application conditions, the task and the driving style. This may also mean that a longer running time can be achieved. The specified running times may also be fallen short of in extreme cases. An interrupted operation (e.g. 30 min. driving, 30 min. standstill) prolongs the running time of the battery.

FSD = operator’s canopy

EPS = Easy Protection System (fold-down operator’s canopy)

EPS Plus = Easy Protection System Plus (hydraulically lowerable operator’s canopy)

Tipping load calculation according to ISO 14397-EN474-3

*The running times of the battery are strongly dependent on the respective application conditions, the task and the driving style. This may also mean that a longer running time can be achieved. The specified running times may also be fallen short of in extreme cases. An interrupted operation (e.g. 30 min. driving, 30 min. standstill) prolongs the running time of the battery.

| savings operating costs: ca. 40 % | charging time: ca. 8 h | run time: up to 5 h |

Operating costs* for the WL20e:

The 20% higher investment costs are amortized with

an average machine service life of

. 2,800 hours of operation.

*Taken into consideration are energy and service costs as well as a battery replacement for the WL20e after about 1,200 charging cycles.

Easy charging:

Everywhere charging: with the onboard charger at every 230V socket.

Charging in-between gets even more effective, it can be charged anywhere and anytime.

Over-night charging: in 6-8 hours the battery is fully charged.

The new AGM battery technology

(Absorbent Glass Matt):

Virtually maintenance-free.

Flexible intermediate charges are more efficiently through higher power flows and improved power consumption.

Charger “Onboard”! – Easy handling due to charge on common 230 V socket.

Extremely safe handling – no leakage possible, no explosive gas formation.

Low sensitivity to high or low outdoor temperatures.

Always in view:

The charge level of the battery is continiously indicated on the display.

Wheel loader expertise down to the last detail.

![]()

![]()

running time are possible with the fully charged, optionally available more powerful battery. The running time greatly depends on the type of application and can therefore vary.

![]()

![]()

Wacker Neuson distinguishes

particularly economical and

environmentally friendly products with the ECO seal.

![]()

![]()

The latest technology for sustainability in construction. Due to the emission-free drive system, it is perfect for applications in the urban sector as well as indoors.

![]()

![]()

The cabins and operator’s canopies of our wheel loaders offer plenty of comfort due to their spacious design and outfitting details.

![]()

![]()

Due to the articulated pendulum joint, the machines are extremely maneuverable andalways have good traction, even in uneven ground conditions.

![]()

![]()

Use the wheel loaders from Wacker Neuson as you need them – the matching hydraulic connections make it possible.

Awards

The electric wheel loader WL20e from Wacker Neuson was awarded gold as a part of the innovation competition at the demopark+demogolf trade fair 2015 in Eisenach, Germany.

The wheel loader WL20e was among the six finalists for the award of the eCarTec Awards 2015 for electromobility in the category of “Electric Vehicles.”

The electric wheel loader WL20e reached the short list of the European Rental Awards in the “Rental Product of the Year” category. The jury highly recommended the wheel loader and praised the market-friendly solution from Wacker Neuson.

![]()

![]()

The electric wheel loader WL20e has been awarded “Highly Commended” in the Environmental Innovation category of the Plantworx Innovation Awards 2017.